Liquid-Liquid separators

Liquid-Liquid Separators

SEP-10

- Flow Rate : 0 to 12 ml/min

- Wetted Parts : Perfluorinated polymers(ETFE, PFA, FEP, PTFE)

- Max Operating Pressure(Mpa) : 2 (290 psi)

- Dead Volume : 400μl

- Demensions(mm) : 77 * 71 * 29

- Precessing Ports : 1/4" UNF - 28 flat bottom

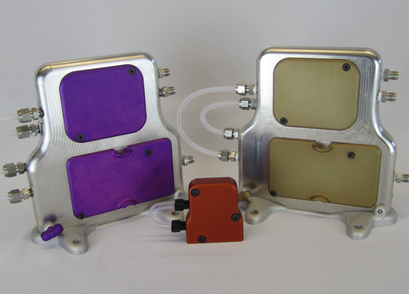

SEP-200-SS

- Flow Rate : 20 to 200 ml/min

- Wetted Parts : SS316 L and FFKM, PTFE, PFA)

- Max Operating Pressure(Mpa): 2 (290 psi)

- Dead Volume : 30ml

- Demensions(mm) : 305 * 196 * 26

- Precessing Ports : Swagelok for ¼” OD

SEP-200-HS

- Flow Rate : 20 to 200 ml/min

- Wetted Parts : Hastelloy C 276 and FFKM, PTFE, PFA

- Max Operating Pressure(Mpa) : 2 (290 psi)

- Dead Volume : 30ml

- Demensions(mm) : 305 * 196 * 26

- Precessing Ports : Swagelok for ¼” OD

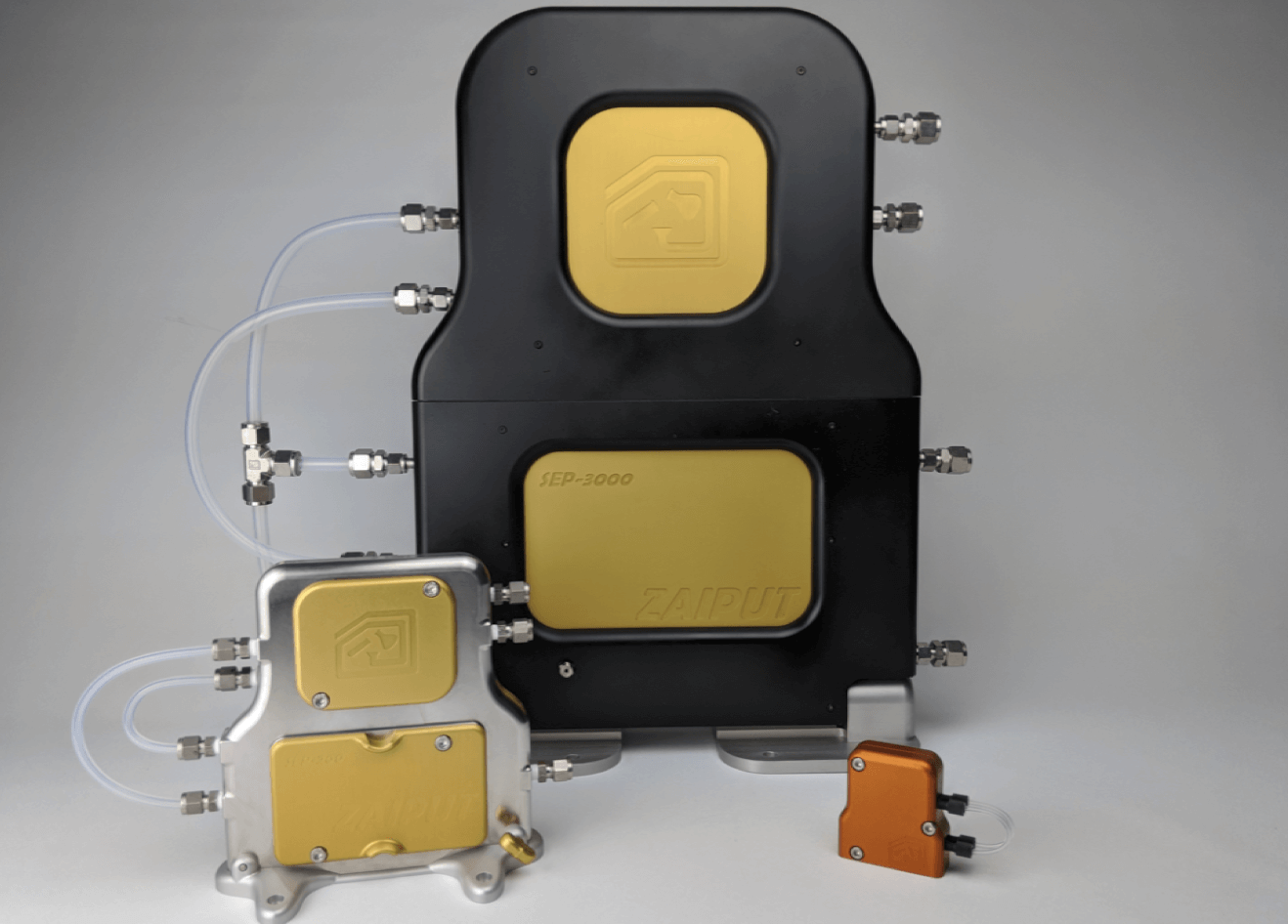

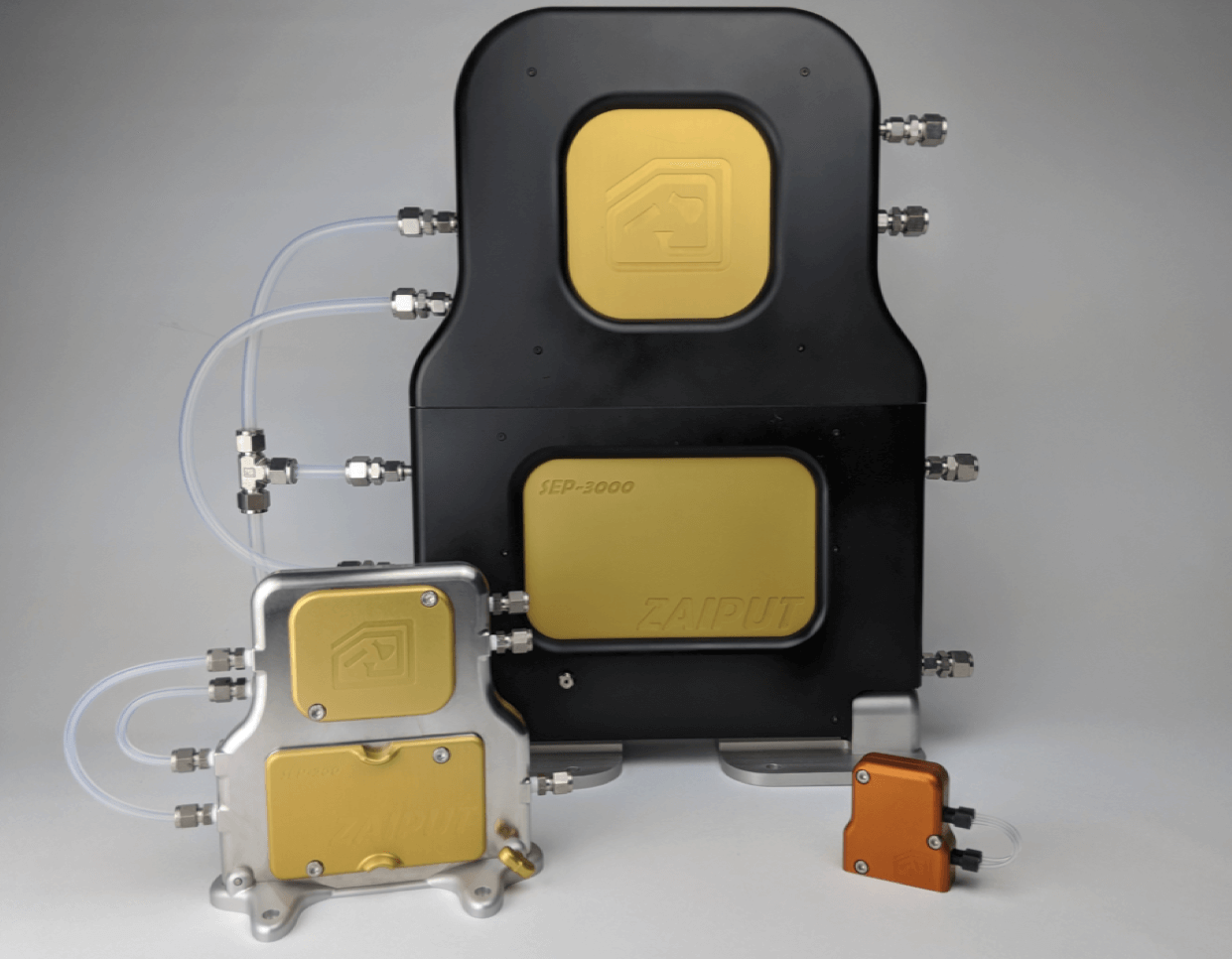

SEP-3000-SS

- Flow Rate : 200 to 3000 ml/min

- Wetted Parts : SS316 L and FFKM, PTFE, PFA)

- Max Operating Pressure(Mpa) : 2 (290 psi)

- Demensions(mm) : 450 * 607 * 150

- Precessing Ports : Swagelok for 1/2” OD

SEP-3000-HS

- Flow Rate : 200 to 3000 ml/min

- Wetted Parts : Hastelloy C 276 and FFKM, PTFE, PFA

- Max Operating Pressure(Mpa) : 2 (290 psi)

- Demensions(mm) : 450 * 607 * 150

- Precessing Ports : Swagelok for 1/2” OD

Important Features

- Bench to plant

Our device is well-characterized and directly scalable from lab to pilot to production. - Separates emulsions with ease

Instead of using agitation to form microdroplets, we improve mixing by using a flow pattern that has a large surface area, thus avoiding emulsions that generally cause separation issues. - Independent of density

The operating principle behind the technology is based on a liquid’s wettable nature, so it works with any liquid-liquid system regardless of their density difference. - Excellent chemical compatibility

Machined in materials with excellent chemical resistance, Zaiput separators work with a wide range of organic solvents, in acidic and basic solutions. - Modular

Plug and play functionality at all scales.

Other Advantages

- Cost effective

Our devices come at a lower price than competing technologies. Our devices also reduce your operating cost thanks to minimal maintenance and highly efficient performance. - Minimal internal volume

Our device eliminates the need for moving or coalescing parts, so it has a drastically reduced dead volume. - Green technology

Our device shows excellent separation performance and high extraction efficiency, reducing solvent consumption. It is suitable for any chemical process, from bulk to high-value chemical industries. - Pressure rating

The metal shell design allows Zaiput separators to be used inline with a pressurized process (up to 300 psi/ 2 MPa).